Premium Industrial Nameplates: Crafted for Quality, Engineered for Excellence

Since 1958, Hallmark Nameplate has been a leading custom printer and industrial nameplate manufacturer, offering unmatched quality and reliability. Specializing in custom industrial nameplates for diverse industries, our extensive materials and processes ensure we meet even the most challenging applications.

With decades of expertise, we collaborate closely to create industrial equipment name plates aligned with your needs. Choose Hallmark Nameplate for superior industrial nameplate solutions.

A Wealth of Nameplate Knowledge and Expert Advice

At Hallmark Nameplate, we simplify the process of selecting the perfect equipment nameplate for your needs. Our comprehensive approach includes detailed insights into materials, finishes, and printing options, tailored to your specific application requirements. Working closely with your team, we create custom solutions that consider every detail, ensuring the highest quality nameplates for your purpose.

Versatile Nameplates for Every Industry and Application

We serve diverse industries, including medical, telecommunications, OEM, government, and military sectors, offering a range of Permanent Product Identification Nameplates, Equipment ID Tags, Barcode Tags, Serial Number Nameplates, and more, suitable for indoor or outdoor use.

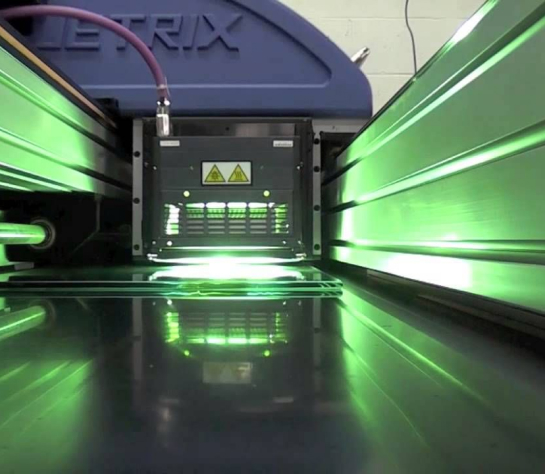

With our extensive inventory of metals and plastics, we specialize in crafting custom industrial nameplates, whether you need rugged nameplates for industry applications or aesthetic panels for branding. Our state-of-the-art facility ensures precision in every detail, from traditional die-cutting to advanced laser cutting, accommodating specific requirements like screw holes, cutouts, or transparent windows. Nameplates are available in sheet form or as individual pieces upon request.

Quality is of the utmost importance, so our robust inspection department guarantees that each custom industrial nameplate meets your exact specifications. We also offer first article inspection to maintain consistency and excellence throughout the production process.

Nameplates, Labels, & Decals We Offer

UL Certified & Classified Labels

Screen Printed Nameplates

Pressure Sensitive Labels & Decals

Military Nameplates

Metalphoto Aluminum Nameplates

Graphic Overlays & Dead Fronts

Domed Labels & Decals

Digitally Printed Nameplates & Labels

QR Code Printing

Industry Certifications and Compliances for Military Nameplates & Asset Labels

We have certified nameplates for industry applications of all types. We are UL certified, RoHS and ITAR compliant and a 3M Preferred Converter. Other certifications include ISO 13485:2016, ISO 9001:2015 and GPI. We are a major supplier of Military Asset Labels, which are designed to meet the strictest MIL SPEC requirements.

Our Certifications

Custom Industrial Nameplates

Personalized Service and Industry Expertise

Learn about the various aspects of custom equipment nameplates in this article, and then contact us with your job details for further information, recommendations, and a quote.

Our team of expert nameplate manufacturers is here to provide exceptional service and answer your questions. We're a trusted supplier of industrial nameplates for commercial, industrial, government, military, and aerospace applications. We provide personalized service and are committed to the success of our customers.

Nameplates Materials & Finishes

Durable Plastic Nameplates

Hallmark Nameplate produces a high volume of polycarbonate and polyester nameplates. One of our clients is a commercial aircraft interior manufacturer. The company makes virtually all the velvet polycarbonate (Lexan) placards that are found inside aircraft cabins (i.e. "No Smoking," "No Stowage" and signs with weight restrictions). We also offer vinyl (PVC) labels.

In addition to the materials mentioned, we can work with customer-supplied custom materials. It's rare that we get a request for a material that we can't print on! If we don't have it in stock, we can order it.

Depending upon the application and variables such as indoor or outdoor environment, proximity to harsh cleaners and other chemicals, industry specifications and branding requirements, our nameplate specialists will recommend the material and finish best suited to your company's needs.

Durable Aluminum Nameplates

Hallmark Nameplate offers premium quality aluminum nameplates in different alloys and finishes. We also offer Metalphoto® nameplates, which are made from photosensitive anodized aluminum.

Of all the available nameplate materials, aluminum is extremely durable, lightweight, versatile, and scratch-resistant, which makes it one of the most widely used materials for nameplates. Aluminum nameplates can stand up to harsh weather, various chemicals, and heavy usage. They can last for many years. Our aluminum nameplates are available in 1000, 1100, 1145, and 5005 aluminum alloys.

Aluminum tags withstand harsh environments and heavy industrial use. Aluminum nameplates can be designed to meet military, ANSI, UL, and CSA specifications. Aluminum is a great nameplate material for clients that want an attractive finish in a hard, tarnish proof and rust-proof material. Aluminum is frequently used for outside applications, but it can also be used inside. Its most common use is for equipment asset tags.

Metalphoto Nameplates – Photosensitive Anodized Aluminum Labels

Metalphoto® is recommended for nameplates that must be extremely durable and unaffected by harsh indoor and outdoor conditions, with high-resolution graphics. Metalphoto nameplates are made from 1100 alloy anodized aluminum, using a special process that doesn’t involve traditional printing. Instead, the image is sealed inside photosensitive, anodized aluminum, which makes the nameplate resistant to UV exposure, high temperatures, chemicals, abrasion, and corrosion. The graphics have the appearance of printed ink but with far greater longevity. Metalphoto nameplates are rated for at least 20 years of outdoor use. Regardless of the environment, the nameplate design won’t ever fade or wear off. This means fewer nameplate replacements and greater compliance with regulatory requirements.

The resilience and lightweight nature of Metalphoto nameplates, and their adherence to strict specifications, make them especially ideal for the aerospace industry. Metalphoto is widely used by the military, government organizations, and the world’s leading OEMs. In addition to Metalphoto nameplates, photo-anodized aluminum can also be used to create rugged, high-resolution control panels, labels, and signs.

Since the image is sealed inside the anodized aluminum and is not printed on top nor etched in, the graphics remain crisp regardless of age or environmental conditions, and the nameplate surface is smooth to the touch. Metalphoto labels are engineered for optimal readability through virtually any operating conditions.

Because of Metalphoto’s proven performance, most industrial, military, and government organizations have specified it for their asset tags and for other applications for more than 65 years. Metalphoto tags are used on everything from offshore oil rigs to NASA’s space station.

Metalphoto Nameplate Uses

There are many uses for Metalphoto. In addition to nameplates, the Metalphoto process is frequently used for control panels and faceplates, product, and equipment ID plates, exterior and interior signs, caution and warning plaques, scales and dials, asset tags, serial number and model number tags, labels with operating procedures, VIN plates, computer tags, bar code labels, and UID data matrix codes.

Metalphoto is widely used for any nameplates that require strict compliance with specifications, such as aircraft labels, off-highway equipment nameplates, military, and commercial ship placards, trailer and shipping container VIN tags, service schematics, load and rating plates, and machine control panels. If you’re looking for a nameplate that provides lasting identification and brand recognition, Metalphoto is a smart choice.

Metalphoto Specifications

The Metalphoto® material is 1100 alloy anodized aluminum. It’s available in thicknesses ranging from .003” to .125” and can be fabricated in any size or shape that’s required. Metalphoto tags can be attached to many kinds of materials with either mechanical fasteners or adhesives. They’re ideal when permanent identification of a product, asset, or process is critical. Metalphoto labels, signs, nameplates, or machine control panels are designed to last throughout the life of the part. For organizations with environmental initiatives, aluminum is a completely recyclable product.

Available Metalphoto finishes include:

- Matte – Dull finish; non-reflective and non-glare

- Satin – Semi-gloss; medium-reflective; slight grain

- #4 – Brushed finish that resembles stainless steel

- Gloss – Mirror-like; highly reflective

Bar code labels typically use the matte finish, whereas equipment panels, nameplates, and signs frequently specify the satin finish. A high gloss finish is often used for plaques and awards.

Metalphoto nameplates are resistant to:

- Abrasion

- Accelerated light and weather

- Accelerated oxygen aging

- Acids

- Cleaning solutions

- Fungus

- Graffiti

- Heat and high temperatures up to 1000 degrees Fahrenheit

- Low temperatures

- Moisture

- Organic solvents

- Saltwater corrosion

- Stains

- Thermal shock

- Ultraviolet radiation (UV)

Metalphoto Receives the Highest Rating from the U.S. Navy

In 2011, the Naval Surface Warfare Center (NSWC), Corona Division, completed a year-long study of 26 commercially available label materials, including Metalphoto. They wanted to determine the environmental survivability of these materials when used as nameplates for Item Unique Identification (IUID). The Navy requires all military assets that are specified under MIL-STD-130 to be marked with a unique barcode that can survive the life expectancy of the equipment it’s attached to. Tested materials included acrylic, polyester, ceramic coated stainless steel, and Metalphoto photosensitive anodized aluminum. These labels were tested for their resistance to abrasion, wide temperature ranges, chemicals, chipping, and salt fog. Except for immersion in MIBK solvent, which none of the labels could withstand, Metalphoto was the only material that passed all tests, and it earned the highest score.

The Metalphoto Nameplate Process

Metalphoto nameplates are made from unsealed pure 1100 alloy anodized aluminum, which is porous in nature. A sub-surface image is created, by exposing and developing an anodized layer that’s saturated with photosensitive silver compounds. The portions of the image that are exposed to light turn black, while any unexposed areas remain the color of the aluminum plate. This is similar to conventional black and white photography. The anodized layer is then sealed, which protects the image inside the hard oxide layer.

The Metalphoto nameplate printing process is as follows:

- Graphics are designed

- High-contrast film negatives are generated

- Anodized Metalphoto plate is exposed to the film negative

- Image is developed and fixed, and the plate is rinsed

- Metalphoto plate is sealed with a special solution

- The nameplate is fabricated and finished

Military, Industrial, and Government Specifications for Metalphoto Nameplates:

- Federal Specification GGP-455B

- MIL-DTL-15024F

- MIL-DTL-19834C

- MIL-P-6906B

- MIL-A-8625F

- MIL-STD-130N

- MIL-P-19834B

- A-A-50271 Class-2 Composition C

- SAE-AMS-QQ-A-250/1

- UL, REACH, and RoHS Certified

Metalphoto is specified by these companies:

- Department of Defense

- Lockheed Martin

- Honeywell

- Boeing

- S. Army

- BF Goodrich

- Underwriters Laboratories Inc. (UL)

- NASA

- Sikorsky (United Technologies)

- General Dynamics

Premium Metalphoto Nameplates for Your Organization

Contact Hallmark Nameplate to discuss your label, nameplate, or control panel project, and to learn more about the benefits of Metalphoto. With more than 60 years of expertise in designing nameplates for every indoor and outdoor environment, we can recommend the best solution for your application and requirements. We will work closely with your team from the design phase through project completion.

Metalphoto Features (test)

- Durable and Long-Lasting – The image, which is silver-halide based, is embedded and sealed inside the anodized aluminum. This image remains clear and readable even after long-term exposure to harsh environmental conditions like extreme weather, sunlight and UV, heat, chemicals, oil, paint, abrasion, dirt and salt spray. The aluminum base is extremely rigid and won’t crack, peel or delaminate.

- Photographic Resolution – High image resolution enables the printing of small marks, with the option to print security features like watermarks and micro text to verify authenticity. This also allows for very small printing where surface area is limited.

- Supports Variable Information – Metalphoto nameplates and labels can be used for unique serialized data, barcodes with any type of symbols or special instructions. This ability streamlines asset tracking and reduces the chance of data entry errors.

Choose Your Finish

Velvet

Protect your label with a rugged material finish or overlaminate for polycarbonate (lexan), vinyl, and polyester (mylar) subtrates

Gloss

Make your graphics stand out with a reflective surface finish. Selective combinations of finishes are available.

The Hallmark Difference

When you choose Hallmark Nameplate, you'll get an expert team of nameplate suppliers, backed by more than 60 years of experience, that will seamlessly integrate with your organization. We walk you through the entire development process to ensure that you have the right nameplate for your specific needs and application.

Get started with a quote from a leading custom industrial nameplate manufacturer, and discover why Hallmark is the top choice for nameplates for industry applications. We look forward to working with you!

INDUSTRIAL NAMEPLATE SAMPLE BOX

We have compiled a variety of our most versatile custom industrial nameplate samples that you can feel and interact with, free of charge.

Within this selection, you'll find an array of samples, each showcasing our wide range of materials and finishes, providing you with ample options to explore.

See first-hand the quality, function, and durability of our industrial nameplates. Request a nameplate sample box today!

FAQ

Ask Our Experts About Equipment Solutions

Our experts are always ready to help. Get in touch with us and we'll find the right solution to meet your needs.