When working in the manufacturing and industrial industry, there are a lot of risks involved. This is due to the operation of heavy machinery and other dangerous equipment and products. At the end of the day, you are liable for any end-user risks.

That is why there is a strong need for manufacturing labels, industrial nameplates, and other product overlays that can be used to alleviate this risk.

From risk mitigation to asset management, discover all of the valuable ways labels and overlays can benefit the manufacturing and industrial industry. Let’s get started.

Common Uses of Overlays and Labels in the Manufacturing Industry

It’s no secret that there is a strong need for overlays, nameplates, and labels in the manufacturing and industrial industry. In fact, overlays and labels are used in almost all aspects of manufacturing. No matter what industry you work with.

They are placed on consumer goods, construction and industrial equipment, food processing and restaurant equipment, IT systems, OEM electronic hardware, telecommunications equipment, and more.

Manufacturing labels and overlays commonly used in this industry include:

- Barcode and UID nameplates

- Product branding tags and promotional nameplates

- Inventory and asset tags

- Model and serial number nameplates

- Tracking labels and tags

- Metal nameplates for equipment identification

- Equipment operating instructions and safety warnings

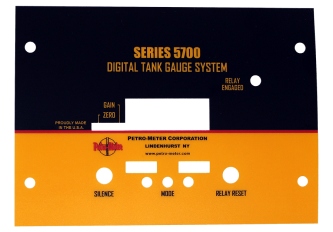

- Control panel overlays

- Precision dials and scales

- Schematics for troubleshooting

So, what type of manufacturers can benefit from using overlays and labels?

Types of Manufacturers That Need Overlays and Labels

Manufacturers in practically every industry use overlays and labels, some of which include:

- Communication equipment manufacturers

- Construction equipment manufacturers

- Consumer goods manufacturers

- Furniture manufacturer

- Industrial appliance manufacturers

- Restaurant equipment manufacturers

While they all use overlays and labels, the type they need may vary. Keep reading to learn more about the types of overlays and labels available and how the manufacturing industry can benefit from each one.

Benefits of Industry-Grade Graphic Overlays

First, let’s talk about graphic overlays. A graphic overlay, also known as a panel overlay, is a critical printed interface on mechanical and electronic assemblies. It allows the user to effectively interact with the device, machine, or equipment.

This top layer visually represents the device’s user interface panel and is the first thing the operator sees. There are various forms, such as a single layer that is backed by adhesive or part of a membrane switch.

These overlays typically include the company name and branding, in addition to product information. Important information to include is IDs and serial numbers, plus instructions for using the device.

Finally, a graphic overlay may also include important safety warnings. This functional user-friendly interface is very important, as it helps define the user experience.

Purpose of Overlays in the Manufacturing Industry

Now let’s discuss how the manufacturing industry uses overlays.

You might already know that graphic overlays used on equipment for manufacturing must be “industry-grade.” Overlays need to be ready to handle heavy daily use and resist harsh chemical environments. This ensures the overlay will last the test of time and never fade when it is needed the most.

Types of machinery that would heavily benefit from the use overlays include:

- Electronic testing devices

- Foodservice equipment

- Safety equipment

- Material handling equipment

- Testing equipment

- Printing devices

- Lathes

- Saws

- Presses

- Milling machines

- Color measurement equipment

- Motor controllers

- Processing equipment

- Commercial and residential appliances

As heavy machinery can pose a potential workplace risk and increased liability for organizations, interfaces must be robust and easy to read, as well as intuitive. This involves a smart design, high-quality graphics, and hearty materials that remain sharp over years of abuse.

Choose the Right Material for Your Overlays

With that being said, let’s take a look at the most beneficial materials for industry-grade overlays.

Anodized Aluminum – Lightweight yet durable, anodized aluminum is suitable for both indoor and outdoor applications. It’s known for its corrosion and abrasion resistance and is lighter than other metals. Anodized aluminum can be customized with various colors and designs.

PhotoSensitive Aluminum (MetalPhoto) – MetalPhoto is extremely durable and unaffected by harsh indoor and outdoor conditions. It includes the process of sealing your image under a sapphire-hard anodic layer to protect it.

Polyester (Mylar®) – Polyester, also known as Mylar, is ideal for harsh indoor and outdoor environments. The material is UV resistant, won’t fade in the sun, is non-yellowing, electrical resistant. It can also withstand extreme temperatures, water, abrasion, and chemicals.

Polycarbonate (Lexan®) – Lexan is a polycarbonate resin thermoplastic material that’s transparent, strong, tough, impact-resistant, and temperature resistant. It’s the best material to use where extreme temperatures and widely varying temperatures are a concern. This material is also resistant to scratches, corrosion, chemical abrasion, and water. It also expands and contracts without damaging the material.

Vinyl (PVC) – PVC vinyl, also known as polyvinyl chloride, is very rigid and extremely durable. However, unless it has UV overlaminate protection, it isn’t suitable for outdoor use. Properties of PVC include resistance to moisture and humidity as well as low cost.

Now that you know all about graphic overlays, it’s time to talk about the importance of industry labels.

Benefits of Industry Labels for the Manufacturing Industry

Businesses in the manufacturing industry use labels to facilitate their manufacturing and inventory tracking. Labels are also used for shipping any products or equipment their business makes. Labels share vital instructions and safety warnings as well as provide quality control.

Typically, labels are placed on manufacturing machines and equipment in order to provide the necessary information. They usually contain barcodes, ownership details, manufacturer’s name, serial number, and maintenance requirements.

Purpose of Labels in the Manufacturing Industry

Now let’s discuss how the manufacturing industry uses labels.

Machinery and heavy-duty equipment require labels that can withstand harsh conditions and meet industry specifications. The manufacturing industry often uses labels for safety and instructional purposes, putting them in facilities and on equipment.

You can get custom industrial labels, tags, nameplates, such as:

- Manufacturing labels

- Factory and machinery labels

- Circuit board and electronics labels

- Engineering labels

- Domed labels

- QC stickers, labels & tags

- QR codes, barcodes, serial number labels

- UL labels

- Occupational Safety and Health Administration (OSHA) safety labels

- Hazard labels

- Security labels

- Instructional labels

Once you have decided the purpose of your label, you can begin to select the material you want to use.

Pick the Proper Material for Your Industry Labels

The best materials for your labels will depend on many factors, including usage, environmental conditions, and the information required. However, here are some of the most common materials used for industry labels.

Polyester (Mylar®) – Polyester, also known as Mylar, is ideal for harsh indoor and outdoor environments. The material is UV resistant, won’t fade in the sun, is non-yellowing, is electrical resistant. It can also withstand extreme temperatures, water, abrasion, and chemicals.

Polycarbonate (Lexan®) – Lexan is a polycarbonate resin thermoplastic material that’s transparent, strong, tough, impact-resistant, and temperature resistant. It’s the best material to use where extreme temperatures and widely varying temperatures are a concern. This material is also resistant to scratches, corrosion, chemical abrasion, and water, and it expands and contracts without damaging the material.

With proper, well-made manufacturing labels and overlays on your side, you can run your business smoothly and safely.

Design Your Manufacturing Labels and Overlays with Hallmark Nameplate

Are you ready to craft the strongest, most reliable industry-grade labels and overlays for your equipment, machinery, and products?

At Hallmark Nameplate, we’ll work closely with your team to learn every detail of your desired application so we can design the best manufacturing labels for your business. We use top-quality materials and printing processes to ensure each order is made to perfection.

Ready to get started? Sign up for a comprehensive FREE quote to find a solution that will meet your specific needs.