With so many nameplate substrate options, it can be hard to tell which is best for your project.

To help you make the most informed decision, we’re continuing our substrate series by taking a closer look at polycarbonate, also known by the brand name Lexan®.

What Are Polycarbonate Nameplates?

Nameplates provide decorative and informative solutions that enhance your product while maintaining quick turnaround times and consistent quality.

Unlike graphic overlays, nameplates typically do not require embossing or extensive engineering, making them faster to produce and more cost-effective, without sacrificing durability or visual appeal.

Polycarbonate is a widely used engineering plastic known for being strong, tough, and flexible, with certain grades offering optical transparency. Because of these properties, polycarbonate is easily molded, thermoformed, and worked into complex shapes, making it an excellent choice for nameplates used in demanding environments.

A Brief History of Polycarbonate

Polycarbonate materials were first discovered in 1898 by German scientist Alfred Einhorn at the University of Munich.

Despite decades of early research, the material wasn’t commercially developed until 1953, when Hermann Schnell of Bayer patented the first linear polycarbonate.

Since then, polycarbonate has become a staple material across engineering, manufacturing, and industrial applications.

Why Choose Polycarbonate for Nameplates?

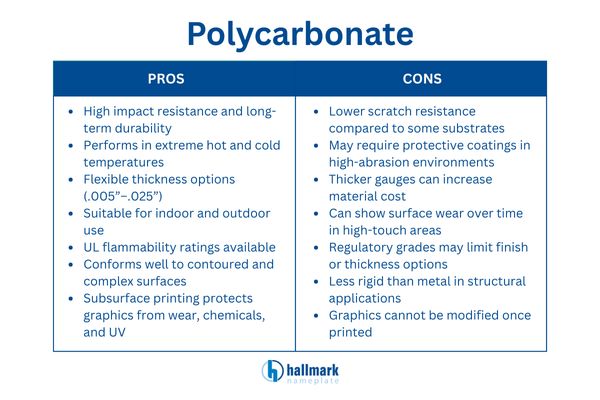

Polycarbonate offers a unique balance of durability, flexibility, and visual performance, with several key benefits that make it one of the most versatile nameplate substrates available.

Engineered for Durability & Performance

Polycarbonate delivers a rare combination of durability, flexibility, and visual performance, making it one of the most versatile substrates available for nameplates.

Its engineering-grade properties allow it to perform reliably in demanding environments while maintaining a clean, professional appearance across a wide range of applications.

Wide Temperature Tolerance

One of polycarbonate’s most significant advantages is its ability to withstand extreme temperatures. It performs well in both high-heat and low-temperature conditions without warping, cracking, or losing structural integrity.

This makes it an excellent choice for nameplates used on manufacturing equipment, outdoor installations, transportation systems, and other environments where temperature fluctuations are common.

Flexible Thickness Options

Polycarbonate is available in a broad range of thicknesses, from .005” to .025”, giving designers greater control over durability, weight, and cost.

Thinner gauges are ideal for lightweight labeling and compact equipment, while thicker options provide added rigidity and impact resistance for heavy-duty or industrial applications.

Versatile Finish Selections

When it comes to appearance, polycarbonate offers unmatched flexibility. It is available in gloss, velvet, and matte finishes, allowing manufacturers to customize the look and feel of a nameplate based on branding goals, lighting conditions, and user interaction.

Whether you need a high-shine, premium look or a low-glare surface for improved readability, polycarbonate delivers consistent, high-quality results.

Indoor & Outdoor Compatibility

Polycarbonate performs reliably in both indoor and outdoor environments.

It resists common environmental stressors such as humidity, temperature swings, and UV exposure, making it suitable for applications ranging from indoor control panels to outdoor equipment housings and enclosures.

Flammability Ratings & Compliance Support

For applications that require regulatory compliance, polycarbonate offers flammability ratings such as UL94 V-2.

These options help manufacturers meet safety and certification requirements without compromising material performance or design flexibility.

High Impact Resistance & Optical Clarity

All of these advantages are reinforced by polycarbonate’s high impact resistance and excellent optical properties. The material is extremely tough and resistant to cracking under stress while still allowing for clear visibility when transparency is needed.

While polycarbonate has lower scratch resistance than some harder materials, its overall strength, resilience, and long service life make it a dependable solution for long-term nameplate applications.

Ideal for Contoured & Complex Surfaces

Engineering plastics like polycarbonate have steadily replaced traditional materials such as wood and metal in many applications. They often equal or exceed these materials in strength while being significantly lighter and easier to manufacture into complex shapes.

If your nameplate needs to be applied to a contoured or irregular surface, polycarbonate is highly recommended. Its flexibility ensures superior coverage and a high-quality finished appearance.

Subsurface Printing for Long-Lasting Graphics

Polycarbonate nameplates are printed on the underside of the transparent material, allowing the substrate itself to protect the graphics.

This subsurface printing process shields colors, text, and images from:

- Cleaners and solvents

- Abrasions and wear

- Extreme temperatures

- Outdoor elements and UV exposure

The result is a durable, economical labeling solution with crisp, vibrant, and precise graphics that stand the test of time.

Easy Forming & Prototyping Benefits

Unlike most thermoplastics, polycarbonate can undergo large plastic deformations without cracking or breaking. It can even be formed at room temperature using sheet-metal-style techniques, such as bending on a brake.

This makes polycarbonate especially valuable for prototyping applications where transparent or electrically non-conductive parts are required, situations where metal simply isn’t an option.

Key Variables We Consider for Your Nameplate

Polycarbonate is just one of many substrate options we evaluate when designing your nameplate.

To ensure the best possible outcome, we consider variables such as:

- Mounting surface type

- Indoor vs. outdoor application

- Finish selection (gloss, velvet, or matte)

- Serialization and barcodes

- Display windows (LED or LCD)

- Available drawings and artwork files

- Domed elements

- UL or CSA requirements

Get Custom Polycarbonate Nameplates

With more than 55 years of experience, Hallmark Nameplate guides you through the entire development process, from initial concept to final production.

Our facility supports both screen and digital printing on materials ranging from .003” to .030”, ensuring precision and consistency at every stage.

Still have questions? Contact Hallmark Nameplate today and experience the highest quality service, from your first inquiry to your finished product.