Previously, we explored a few substrates available for your next nameplate project. While those materials are excellent for certain applications, there are many other substrates worth considering.

In this installment of our series, we focus on vinyl, a flexible, durable, and cost-effective material that offers a wide range of applications for both indoor and outdoor use.

Nameplates provide decorative and informative solutions that enhance your product, all while offering quick turnaround times without sacrificing quality. Compared to graphic overlays, vinyl nameplates can be produced faster, at a lower cost, and with high-quality consistency.

What is Vinyl?

Vinyl is a synthetic plastic material that is highly versatile and widely used in industrial and commercial applications. When used for nameplates, vinyl can be:

- Rigid or flexible, depending on your needs

- Available in thicknesses from .004″ to .030″

- Offered in gloss or matte finishes

- Suitable for indoor use and outdoor use with a UV over-laminate

Its flexibility allows vinyl to conform to a variety of surfaces, including concave or convex areas, while maintaining strong adhesion and durability.

Benefits of Vinyl Nameplates

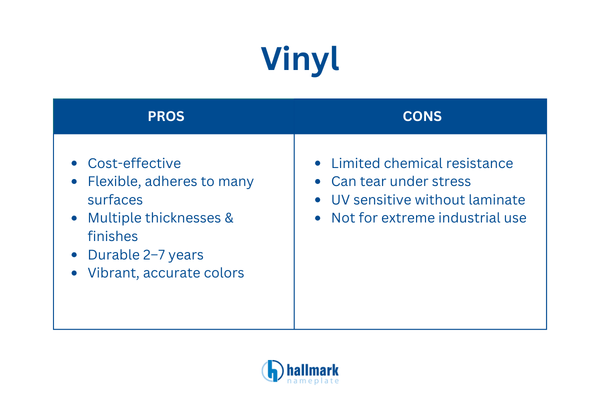

Vinyl nameplates are a versatile and practical solution for a wide range of applications, and their popularity stems from a combination of performance, affordability, and aesthetic appeal. Here’s a closer look at the key benefits.

1. Cost-Effective

One of the biggest advantages of vinyl is its affordability. Compared to other substrates, vinyl is generally less expensive to produce, making it an ideal choice for projects with tighter budgets or high-volume needs.

This cost-effectiveness doesn’t mean sacrificing quality; vinyl nameplates can still offer sharp graphics, vibrant colors, and consistent performance. Whether you’re producing hundreds of decals, asset tags, or promotional labels, vinyl delivers excellent value.

2. Flexible Applications

Vinyl is incredibly adaptable, capable of adhering to a wide variety of surfaces and textures. Its flexibility allows it to conform to flat, concave, or convex surfaces, making it suitable for equipment, machinery, or signage that may have irregular shapes.

Vinyl performs well both indoors and outdoors, and when paired with a UV overlaminate, it can withstand exposure to sunlight without fading. This versatility makes it a go-to option for products ranging from industrial machinery to event banners.

3. Variety of Finishes and Thicknesses

Customization is a key advantage of vinyl. It’s available in a range of thicknesses, from ultra-thin (.004″) to more robust options (.030″), allowing it to suit different functional needs. You can also choose from gloss, matte, or even velvet finishes to match your product aesthetics or branding guidelines.

This flexibility means your vinyl nameplate can seamlessly integrate into your design while maintaining the durability and readability required for its intended use.

4. Durability

Vinyl nameplates are designed to last. Depending on environmental factors and application, they can maintain their appearance and adhesion for approximately 2–7 years.

While vinyl is not as resistant to chemicals as some other substrates, it handles everyday wear and tear exceptionally well. Its resilience makes it perfect for both temporary applications, like event signage, and longer-term needs, such as company asset tags or outdoor decals.

5. Visual Appeal

A major benefit of vinyl is its ability to deliver eye-catching graphics and precise color reproduction. An experienced manufacturer ensures accurate color matching, giving you access to virtually any hue imaginable.

This makes vinyl ideal for branding purposes, logos, and promotional graphics where maintaining a consistent visual identity is critical. Its smooth surface allows for high-resolution printing, ensuring text, logos, and other design elements look sharp and professional.

6. Lightweight and Portable

Beyond aesthetics and durability, vinyl is also lightweight and easy to handle, making installation quick and straightforward. This is especially useful for banners, event signage, and temporary applications where mobility and ease of setup are important.

7. Eco-Friendly Options

Modern vinyl production techniques often include eco-solvent or water-based inks, which reduce environmental impact while still providing durable, vibrant graphics. This allows businesses to create high-quality nameplates without compromising on sustainability.

Uses of Vinyl

Overall, vinyl’s combination of affordability, flexibility, durability, and visual quality makes it an excellent choice for a wide variety of projects, from industrial labeling to promotional and decorative applications.

It is most often used to promote a company’s logo, a special promotion, event, team, or school. Since vinyl is both flexible and portable, you could see a vinyl banner just about anywhere, such as billboards, table banners, trade show banners, building banners, street banners, festival banners, and stadium flags.

Its flexibility and portability make vinyl a great choice for trade shows, festivals, stadiums, and more.

Vinyl Nameplate Options

Vinyl nameplates are offered with a variety of options to meet your project requirements:

- Surface: The type of surface it will be mounted to

- Indoor or outdoor applications (UV over-laminate available for sun exposure)

- Finish options: Gloss, matte, or velvet

- Thickness: Ranging from .004” to .030”

- Special features: Serialization, barcodes, display windows (LED/LCD), domed elements

- Assets: Drawings and art files available

- Compliance: UL or CSA requirements, if needed

This flexibility ensures that your vinyl nameplate is perfectly suited for your product, branding, or industrial requirements.

How Vinyl Nameplates are Created

Vinyl nameplates can be produced using digital printing or screen printing. Both methods allow for precise customization, ensuring your vinyl nameplate meets your exact specifications.

Digital printing

This process utilizes aqueous (water-based), eco-solvent, solvent-based, or UV-curable inks. Solvent and UV inks provide superior weather and UV resistance.

Large-format inkjet printers and grand-format printers can produce pieces wider than 2.5 meters, with some machines capable of printing up to 3,000 square feet per hour.

Screen printing

Involves applying ink through a stencil or screen, one color at a time. This process can be done manually or with automated multi-color presses for consistent, high-quality results.

Get Custom Vinyl Nameplates

Vinyl is one of the most versatile substrates available for nameplates, offering flexibility, durability, and cost-effectiveness. Whether you need a vinyl nameplate for a company logo, warning decal, or promotional banner, Hallmark Nameplate has the experience and resources to guide you through every step of the process.

With over 55 years in the industry, we ensure that your nameplate is crafted to meet your specific needs — from the type of surface it will be mounted on to the ideal finish, thickness, and compliance requirements.

When it’s time to start your next project, trust Hallmark Nameplate to deliver the right vinyl solution for your application.