If you are in the market for a custom circuit board, you’ve no doubt heard the term “box build.” Box builds are the metal and plastic boxes used to house circuit boards and other delicate electronics. Oftentimes, these boxes are purchased from a different company than the one who actually made the electronics. However, it may be more convenient to purchase both components from the same company. Box builds are custom-made based on the dimensions of the electronics, and they require a variety of different parts such as injection molded plastic and sheet metal. These boxes are subject to extensive quality control procedures before being shipped to the buyer. To learn more about box builds, read on.

Protecting Delicate Electronics

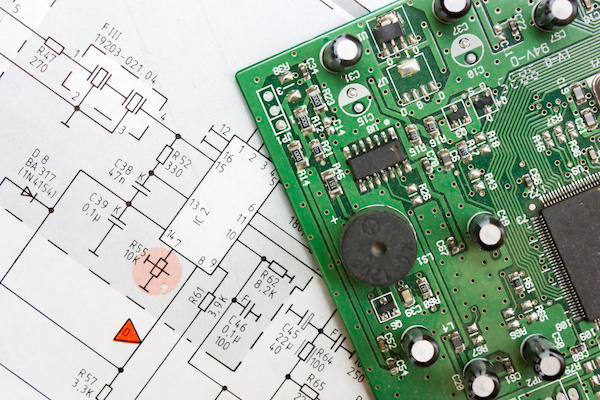

Box builds are manufactured primarily to protect delicate electronics. As you no doubt already know, circuit boards and associated parts are very sensitive to vibrations, liquid spills, and many other dangers. Custom circuit boards are not cheap, so protecting them properly is vital. A custom-made box build is the best way to do this.

Purchasing a Box Build from the Company Making the Electronics

As previously mentioned, many box builds are purchased separately from the electronics. However, Hallmark Nameplate makes both custom circuit boards with associated electronics and box builds. Taking advantage of this service will save you time and money. You don’t have to worry about getting your electronics and then waiting to get the box necessary to protect them. You can get the completed assembly all at once. Not only can you save time and money, but the box will fit more precisely if the company making the electronics designs the box around the exact dimensions of these parts.

Designing the Box

For a company to design a box build, they need the exact dimensions of the parts and they need to know information about how the electronics will be used and where they will be installed. If you have the same company make the electronics and the box, they will likely already have all this information. If you indicate that you would like a company like Hallmark Nameplate to make the box at the same time as you place the order for the electronics, the entire process will be streamlined to make it quicker and more effective.

Parts Required for a Box Build

As previously mentioned, several parts are required to complete a box build. The main parts are sheet metal fabricated pieces and injection molded plastic. These make up the majority of the box material. However, they are not the only parts of the box. Cable assemblies and PCBs are also necessary to build a proper box. There may be other parts required, as well. This depends on the specific build. A special type of glue is often required for these boxes. Hallmark Nameplate uses only specially made glue that will not interfere with the operations of the electronics in any way, shape, or form.

Quality Control

Reputable manufacturers, such as Hallmark Nameplate, put everything they make through rigorous quality control procedures. A custom box build is not cheap, so you want it to work perfectly right away. All of Hallmark’s box builds are inspected using Auto Optical inspection as well as x-ray testing. Our X-ray testing uses state-of-the-art Yestech devices to inspect every circuit board and array. Everything is also hand-inspected by trained quality control professionals. Only after the equipment has passed all these checks does it go out to the customer. This ensures a very low failure rate for items we manufacture.

Vertically Integrated Manufacturing from Hallmark Nameplate

Hallmark Nameplate offers fully integrated manufacturing services. This means we can take your prototype from the design stage to the circuit board to full visual electronic testing to box build. We can do everything in-house, which saves you time and money. It also reduces the amount of effort you have to put into getting that device you want. We have a complete ISO9001: 2008 operation, which means everything is up to the latest and most stringent industry standards. Of course, we also have extensive and highly advanced quality control checks that are always applied after the manufacturing has been completed.