Membrane switch panels and the switches themselves are the essential interfaces between machines and operators. Well-designed panels ensure that operation is as simple and intuitive as possible. Their clear instructions and feedback are often essential for keeping workers safe, as well.

We are highly experienced membrane switch manufacturers. For more than 60 years, our company has specialized in membrane switch printing for a variety of industries, including:

- Aerospace

- Medical

- Automotive

- Computer

- Telecommunications

- Food Service

No matter what your unique needs are, our team of experienced experts will work with you to create custom switch panels that make it easy for operators to get the most out of their machines.

How We Construct Custom Membrane Switches

While our industry experience is always helpful, we appreciate that no two companies are the same.

So, before walking you through all of your options, we'll start by listening to what you need from your custom membrane switches and membrane switch panels.

Only then will we go over the following aspects of a membrane keyboard's anatomy:

- Graphic Overlay - This is the interface operators will interact with when using your machines. We make these out of polyester instead of polycarbonate because it is a much more chemically resistant material and offers superior flex life.

- Top Circuit Layer - For the initial circuit layer, we use silver-filled electrically conductive and dielectric inks printed on heat stabilized polyester that's between 0.005 and 0.007 inches thick.

- Overlay Adhesive - We utilize an acrylic adhesive to connect the graphic overlay to the switch's top circuit layer.

- Circuit Spacer - This piece goes between the top and bottom circuit, ensuring the switch remains open until an operator presses the keypad. We use polyester for the spacer, applying adhesive to both sides.

- Lower Circuit Layer - Similar to the top circuit layer, this piece includes a flexible stem that interconnects to controller PCBs (Printed Circuit Boards) or other electronic components.

- Rear Adhesive Layer - This adhesive bonds the membrane switch to your machine's enclosure, panel, or housing. Our team will recommend the best option based on factors unique to your equipment (e.g. operating environment), so the adhesive is sufficient to keep the switch in place.

- Rigid Support Layer - Some applications may require additional structural integrity via an extra layer of support. Again, our team of designers will assess the relevant factors and recommend if this extra step is necessary.

While this describes the typical makeup of membrane switch panels, we specialize in custom construction at our membrane switch factory. When designing yours, we'll draw from both our industry expertise and your input.

Hybrid Parts

Get Expert Help with Designing Your Membrane Switches

The function of a membrane switch may be straightforward, but effectively designing them requires an in-depth understanding of the aforementioned features and eight other important considerations.

As part of our custom switch printing services, we'll explain each of these in detail, including making recommendations for your unique machines.

The Degree of Tactile Feedback

A membrane switch with tactile feedback lets the operator know when a button has been pushed. They can literally feel if they've applied enough pressure for the switch to take action.

This feedback makes operation easier, as the worker can keep their eyes on a screen, work area, etc.

We offer a wide range of materials and button sizes to create the exact amount and type of feedback you want for your switches. Our designers can also alter the amount of actuation force required to press down on a button.

In some cases, tactile feedback isn't pragmatic. That's when we recommend sound or light components to confirm activation for operators. Even if tactile feedback is a good idea, adding a light component means that, with just a glance, someone can see if a button has been activated or not.

Complex Membrane Switch Designs

A basic switch and membrane switch panel aren't always enough for an effective interface.

Instead, a multilayered switch may be necessary, which could entail:

- Shielding

- ESD (Electrostatic Discharge Materials)

- EMI (Electromagnetic Interference)

- Embedded Components

- LEDs

- Resistors

- Light Sensors

- Programmable Chips

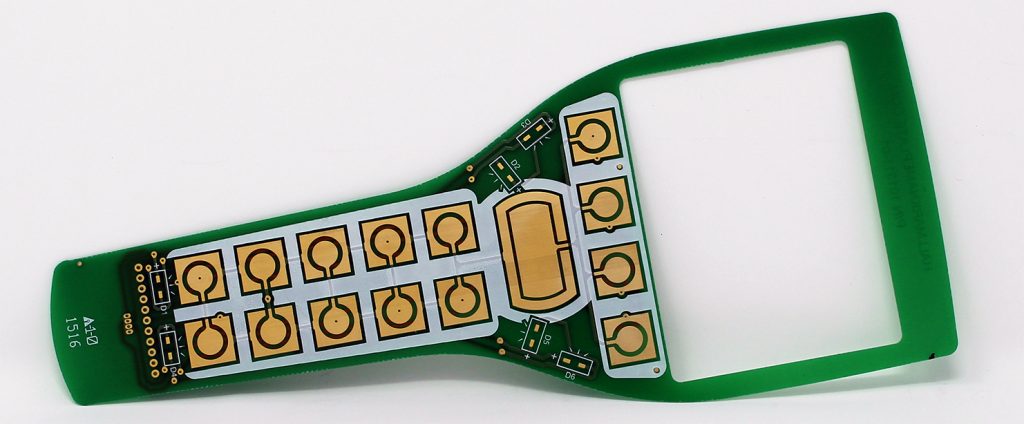

For these kinds of custom membrane keyboards, we usually utilize PCBs or copper flex to create the circuit layer. Among other things, this gives us endless options for creating whatever kinds of electronic components our clients demand.

Copper Flex Membrane Switches

Our copper flex membrane switches are made by laminating copper to underlying substrates. Precise conductive traces are then imprinted into those substrates to create a more flexible, durable circuit, perfect for soldering compounds.

Printed Circuit Boards and Printed Circuit Board Assemblies

Many applications require switches with much smaller, high-density components. This is when our PCBs and printed circuit board assemblies (PCBAs) are essential.

Our designers utilize them to turn even the most complex of interfaces into user-friendly membrane switches and panels.

LED Backlighting Options for Custom Membrane Switches

Adding LED backlighting to your membrane keyboards makes it easier for the operator to see the interface, even when working in environments where visibility suffers.

However, to work most effectively, this backlighting must entail the right light quality, intensity, color, and coverage for the specific environment in question.

Visual Considerations for Membrane Switch Design

Everyone wants an aesthetically pleasing switch for their machines, but visuals also play an important role in improving their operation.

At Hallmark Nameplate, we create practical visuals by leveraging:

- Color Management

- Digital Printing

- Embossing

- Finishes

- Inks

Our technology and approach ensure consistency across all of your machines. We can even color match to a color swatch, the Federal Standard Guide, Pantone Matching System, or your bezel.

Environmental Considerations for Membrane Switches

We pride ourselves on designing membrane switches that aren't just easy to use but easy to use for years and years. Even if your operators will interact with them multiple times an hour, we can create custom switches that will easily keep pace.

Talk to an Expert About Your Custom Membrane Switches

Custom membrane switches should add to your machine's aesthetics, make them safer for users, and ensure that operators can get the most out of every feature.

However, as you just saw, achieving this result means understanding all of your options, including which ones are most important for your specific machines.

That's why we do more than just design and manufacture membrane switches. We also provide expert consultations, so you're 100% confident in what you've ordered long before we start creating it.

Call us today at 352-383-8142 or fill out this simple form for a free quote and to find out more about how we can help your business.

Our Certifications

MEMBRANE SWITCH SAMPLE BOX

We've gathered a selection of our most versatile membrane switch samples, available to you at no cost.

These samples provide a hands-on experience for you to appreciate the quality, functionality, and durability of our membrane switches. When you interact with these samples, you can feel the precision and responsiveness that define our products.

Don't miss this opportunity, request your sample box today to explore our top-tier custom membrane switches, make informed decisions, and experience their quality firsthand.